Troubleshooting Slow Mycelium Colonization

Understanding Mycelium Colonization Basics

Mycelium colonization is the process by which fungal networks spread through a substrate, breaking down organic matter to fuel growth. This phase is critical for mushroom cultivation, as delays can stall or even ruin a crop. Colonization speed depends on factors like environmental conditions, substrate quality, and genetic strain health. Understanding these variables helps identify why growth might lag. For example, mycelium thrives in specific temperature and humidity ranges—deviations can trigger dormancy or stress. A grasp of these fundamentals sets the stage for effective troubleshooting.

Environmental Factors: Temperature and Humidity

Mycelium growth is highly sensitive to temperature fluctuations. Most strains favor 75–80°F (24–27°C), with deviations outside this range slowing metabolism. Cooler environments delay enzymatic activity, while excessive heat risks denaturing proteins. Humidity levels around 90–95% prevent substrate drying but require balance—over-saturation limits oxygen exchange. Use calibrated thermostats and hygrometers to maintain consistency. Insulating grow rooms or using heating mats can stabilize conditions. Remember: Stability is key—sudden shifts stress mycelium, leading to sluggish colonization.

Substrate Preparation and Composition

The substrate’s nutritional and physical structure directly impacts colonization. Lignin-rich materials like hardwood fuel slow-growing species, while fast colonizers prefer cellulose-heavy straw or coffee grounds. Improper hydration—a common mistake—creates anaerobic pockets. Aim for 60–70% moisture content; a squeezed handful should release only a few drops. Sterilization is equally vital: incomplete pasteurization invites competitors. Adjust recipes based on mushroom species—oyster varieties tolerate diverse substrates, while shiitake demands hardwood sawdust. Tailoring substrate composition prevents bottlenecks in growth.

Identifying and Preventing Contamination

Contaminants like mold, bacteria, or mites often explain stalled growth. Green or black patches signal Trichoderma or Aspergillus, while sour odors indicate bacterial blooms. Inspect jars daily under bright light. Contamination risks rise with poor sterile technique—always work near a flame or laminar flow hood. Preemptive measures include adding 1% hydrated lime to substrate pH to deter competitors. Isolate contaminated containers immediately. If using grain spawn, look for uneven colonization or slimy textures. A zero-tolerance approach preserves healthy cultures.

Assessing Spawn Quality and Inoculation Techniques

Weak spawn leads to feeble colonization. Healthy grain spawn appears fully colonized, smells earthy, and shows no discoloration. When inoculating substrate, distribute spawn evenly—clumps create uneven growth. Use 10–20% spawn-to-substrate ratios for optimal coverage. Liquid culture syringes should deposit droplets near jar edges to spread outward. Avoid over-handling spawn, which damages hyphae. For grain-to-grain transfers, select vigorously growing mycelium. High-quality spawn acts as a growth accelerator, while compromised cultures doom the process from the start.

Optimizing Gas Exchange and Airflow

Mycelium requires oxygen for respiration but produces CO2 as waste. Inadequate gas exchange suffocates growth. Use breathable microppose filters or polyfill-stuffed jar lids. Avoid sealing containers—mycelium isn’t photosynthetic but still needs airflow. In bulk substrates, periodic fresh air exchange (FAE) prevents CO2 buildup. However, excessive airflow dries substrates. Balance is achieved with timed fans or manually flipping lid filters. CO2 levels above 10,000 ppm stagnate growth; simple passive ventilation often restores momentum.

Managing Substrate Moisture Levels

Moisture is a double-edged sword. Overly wet substrates promote anaerobic bacteria, while dry conditions halt enzymatic activity. Field capacity—the ideal moisture level—varies by substrate. Coco coir holds water well; straw requires longer soaking. Use a press test: squeezed substrate should cling without dripping. If over-hydrated, spread material to air-dry pre-inoculation. Hydration during colonization isn’t feasible without re-sterilization. Hygrometer probes inserted into substrate (via sterile ports) help monitor internal moisture without disturbing mycelium.

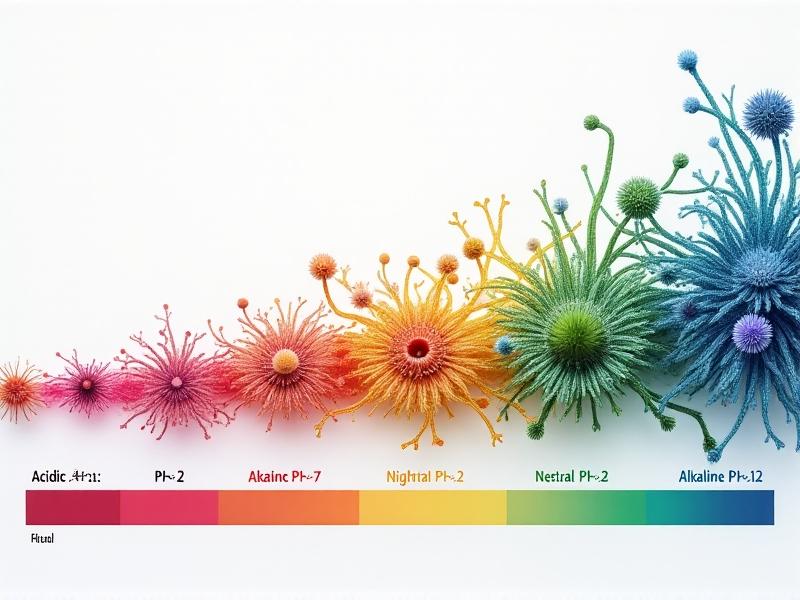

The Role of pH Balance in Mycelium Growth

Most mycelium prefers slightly acidic conditions (pH 5–6.5). High alkalinity inhibits enzymes; low pH risks metal toxicity. Test substrate pH post-hydration using strips or a meter. Adjust with calcium carbonate (to raise) or citric acid (to lower). Coffee grounds, naturally acidic, benefit alkaline-tolerant species like oyster mushrooms. Lime-treated substrates resist contaminants but require pH monitoring. Buffered substrates maintain stability longer. Remember: pH shifts occur during sterilization—always measure after cooling.

Genetic Strains and Their Impact on Colonization Speed

Genetics dictate a strain’s vigor and environmental preferences. Commercial oyster mycelium colonizes rapidly (10–14 days), while morels take months. Isolating rhizomorphic (strand-forming) mycelium from tomentose (cottony) growth on agar plates selects faster colonizers. Avoid successive generations of grain transfers, which weaken strains. Purchase cultures from reputable labs and document performance. Slow colonization might signal a mismatched strain—switch varieties if environmental tweaks fail. Genetics are the blueprint; even perfect conditions can’t override a sluggish strain.

Case Studies: Real-World Troubleshooting Scenarios

Case 1: A cultivator’s rye grain jars stalled after 20% colonization. Problem: Room temps dropped nightly to 65°F. Solution: Added a seedling mat set to 78°F. Colonization completed in 10 days. Case 2: Mycelium in sawdust grew asymmetrically. Cause: Clumped spawn during inoculation. Breaking up spawn pre-mixing fixed uneven growth. Case 3: Persistent stalling in coir/verm substrate. Testing revealed pH 7.2 from lime overuse. Adjusting to pH 6.0 with citric acid resolved the issue. Each case underscores methodical diagnosis—change one variable at a time.