Preventing Competitor Fungi in Substrate

Understanding Competitor Fungi in Substrates

Competitor fungi are invasive microorganisms that colonize substrates, outcompeting beneficial or cultivated species for resources. These fungi thrive in organic-rich environments, such as agricultural substrates used for mushroom cultivation or crop production. Common examples include Trichoderma , Penicillium , and Aspergillus , which reproduce rapidly through airborne spores. Their presence often leads to reduced yields, contamination of entire batches, and financial losses. Understanding their biology—such as spore dispersal mechanisms and preferred environmental conditions—is the first step in designing effective prevention strategies.

Key Fungal Species Threatening Substrate Health

Trichoderma harzianum is a notorious competitor in mushroom farming, recognizable by its rapid green sporulation. Penicillium species produce blue-green spores and thrive in high-moisture environments, while Aspergillus prefers warmer temperatures. Each species has distinct stress tolerances: Trichoderma , for instance, can survive partial sterilization. Regular microscopy or DNA testing helps identify contaminants early. Recognizing visual cues—like color changes or abnormal smells—enables growers to act before infestations escalate.

Sterilization Techniques for Eliminating Pathogens

Sterilization eradicates all microbial life using high heat, chemicals, or radiation. Autoclaving substrates at 121°C (250°F) for 60–90 minutes is industry-standard, but energy-intensive. Chemical sterilants like hydrogen peroxide or chlorine dioxide are effective for heat-sensitive materials. Gamma irradiation, though less accessible, ensures deep penetration. A drawback? Sterilization can also destroy beneficial microbes, leaving substrates vulnerable to reinfestation if not handled post-treatment.

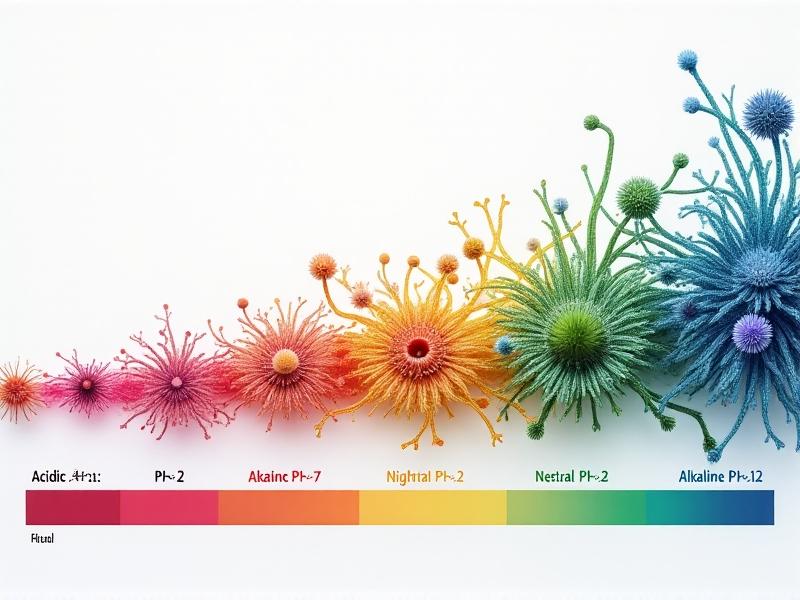

Pasteurization: A Gentler Approach to Microbial Control

Pasteurization heats substrates to 60–80°C (140–176°F) for several hours, eliminating pathogens while preserving heat-tolerant beneficial microbes. Ideal for straw or compost, this method reduces energy costs and supports a balanced microbiome. However, improper temperature control can leave pockets of contamination. Many growers combine pasteurization with pH adjustment—for example, hydrated lime raises alkalinity, deterring acid-loving fungi.

Optimizing Temperature to Discourage Fungal Growth

Most competitor fungi flourish between 20–30°C (68–86°F). Maintaining substrates outside this range—via refrigeration or localized heating—can inhibit their growth. For example, oyster mushroom mycelium thrives at 24°C but stalls Trichoderma growth below 18°C. Thermal sensors and automated climate systems enable real-time adjustments, though redundancy measures are critical to prevent equipment failures.

Managing Humidity and Moisture Levels Effectively

Fungi require moisture to germinate spores and spread. Keeping substrate moisture between 50–70% prevents waterlogged conditions. Automated misting systems with fail-safes, paired with hydrophobic substrates like coconut coir, reduce risks. Proper drainage layers in grow bags or trays are essential—standing water invites contamination even in otherwise optimal environments.

Leveraging Beneficial Organisms for Natural Suppression

Introducing Bacillus subtilis or Streptomyces species creates a microbial shield against invaders. These bacteria secrete antifungal compounds while competing for resources. Inoculating substrates with beneficial fungi like Gliocladium can also crowd out competitors. This approach, integrated with organic farming practices, reduces reliance on harsh chemicals.

Substrate Selection and Preparation Best Practices

Materials like hardwood sawdust resist contamination better than nutrient-dense soybean hulls. Pre-composting substrates for 7–10 days encourages beneficial thermophilic bacteria that outcompete fungi. Smaller particle sizes ensure even heat distribution during sterilization, while avoiding overly fine textures that impede airflow.

Sanitation: Cleaning Tools, Surfaces, and Hands

Pathogens often enter through contaminated tools or clothing. Establishing a sanitation station with footbaths, UV sterilizers, and alcohol-based hand sanitizers minimizes cross-contamination. Critical surfaces should be cleaned with 70% isopropyl alcohol or quaternary ammonium compounds. Regular audits ensure compliance, especially in high-traffic areas.

Real-World Success Stories in Fungal Prevention

A Canadian mushroom farm reduced Trichoderma outbreaks by 90% after implementing HEPA air filtration and staggered harvest cycles. In Southeast Asia, rice straw pasteurization combined with neem oil extracts doubled shiitake yields. These cases highlight the importance of tailored, multi-layered strategies.