pH Meters: Accuracy for Mushroom Cultivation

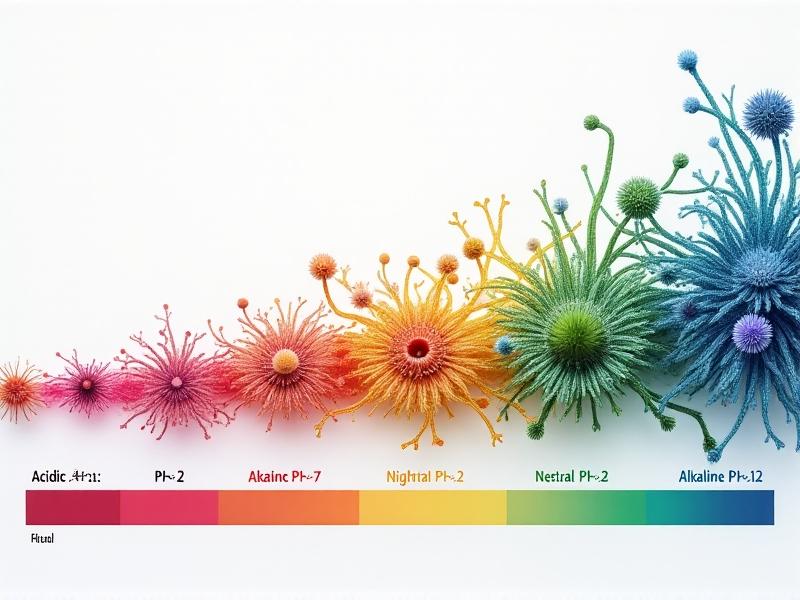

The Critical Role of pH in Mushroom Cultivation

Mushroom cultivation is a delicate dance of environmental factors, with pH playing a starring role. Unlike plants, mushrooms thrive in slightly acidic conditions, typically between pH 5.5 and 6.5. Deviations outside this range can stunt mycelium growth, invite contaminants like molds, or even kill developing fruiting bodies. For species like shiitake or oyster mushrooms, even minor pH fluctuations impact yield and quality. This precision demands tools like pH meters, which offer real-time data to maintain optimal conditions. Understanding why pH matters—from nutrient absorption to microbial competition—is the first step toward mastering mushroom cultivation.

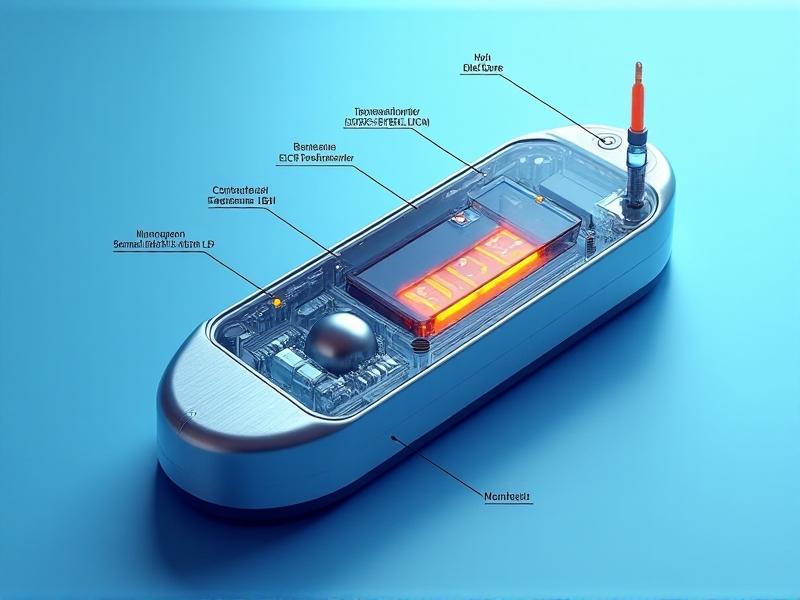

How pH Meters Work: Science Behind the Tool

Modern pH meters measure hydrogen ion activity using a glass electrode and reference cell. When submerged in a solution, the electrode generates a voltage proportional to pH, which the meter converts into a digital reading. Key components like the sensitive glass bulb and internal solutions require careful handling to avoid drift or damage. Advanced models feature automatic temperature compensation (ATC) to adjust for heat’s effect on readings—a must for steam-sterilized substrates. While cheaper strips or liquid tests exist, meters provide the precision needed for repeatable, large-scale mushroom farming.

Optimizing Substrate pH for Mycelium Growth

Mushroom substrates—such as straw, sawdust, or compost—require pH adjustments before inoculation. Lime raises pH for species preferring neutrality, while gypsum or coffee grounds add acidity. Testing multiple points in mixed substrates is crucial, as clumping creates pockets of imbalance. For example, oyster mushroom substrates often target pH 6.0–6.5 post-pasteurization. Post-colonization pH shifts also matter: mycelium excretes enzymes that acidify substrates, which can trigger fruiting. Regular meter checks help growers time harvests and avoid over-acidification that harms later flushes.

Factors Affecting pH Meter Accuracy

Even premium pH meters falter without proper care. Temperature extremes skew readings, necessitating ATC-enabled devices. Contaminated probes—coated in substrate particles or oils—create sluggish responses. Dried-out electrodes, a common oversight during storage, degrade sensitivity. Calibration frequency matters: high-use environments demand weekly checks with buffer solutions. Additionally, low-quality meters may lack double junctions, making them prone to reference cell fouling in organic-rich substrates. Recognizing these pitfalls ensures reliable data for critical cultivation decisions.

Calibration and Maintenance Best Practices

Calibration transforms a pH meter from a guesswork gadget to a precision tool. Use fresh buffer solutions (pH 4.0, 7.0, and 10.0) monthly or after intensive use. Rinse probes with distilled water between tests to prevent cross-contamination. Storage matters: keep electrodes hydrated in KCl solution, never tap water. For stubborn residues, soak probes in enzymatic cleaner. Log calibration dates and readings to spot drifts early. Proactive maintenance doubles a meter’s lifespan and prevents costly cultivation errors from unnoticed inaccuracies.

Digital vs. Analog: Choosing the Right Meter

Digital pH meters dominate modern grows for their ±0.01 resolution and data-logging features. However, analog models—with their rugged design and no-battery reliability—still serve small-scale growers. Key considerations include measurement range (ensure 0–14 coverage), durability (waterproof models for humid grow rooms), and replaceable electrodes. For Lion’s Mane or Reishi cultivators using hot water extracts, high-temperature tolerance is vital. Budget-conscious growers can start with pocket meters but should prioritize replaceable probes over disposable units.

Step-by-Step Guide to pH Testing in Mushroom Substrates

- Collect substrate samples from multiple depths/locations.

- Mix samples with distilled water (1:5 ratio) and stir.

- Let the slurry settle for 10 minutes, then decant liquid.

- Calibrate the meter using fresh buffer solutions.

- Immerse the probe, wait for stabilization (30–60 seconds).

- Record the pH and adjust substrate with amendments if needed.

- Re-test after amendments to confirm target pH.

Common Mistakes and How to Avoid Them

Rookie errors plague pH management. Testing only once post-sterilization ignores natural drifts—monitor weekly. Over-reliance on meters without verifying with litmus strips leads to ‘false precision.’ Forgetting temperature compensation in pasteurized substrates gives deceptive readings. Letting probes dry out between uses degrades accuracy. Lastly, overcorrecting: adding too much amendment creates pH rollercoasters. Patience and redundant checks keep substrates in the Goldilocks zone.

Future Trends: Smart pH Monitoring in Mycology

IoT-enabled pH sensors are revolutionizing large-scale mushroom farms. These devices feed real-time data to apps, triggering alerts when substrates veer off-range. Some integrate with automated amendment dosers for hands-off adjustments. Researchers also explore AI models that predict pH shifts based on mycelium growth rates. As sustainability gains traction, expect more meters made with biodegradable components—like bamboo housings—to reduce e-waste in the mushroom industry.