pH Adjustment to Deter Pathogens

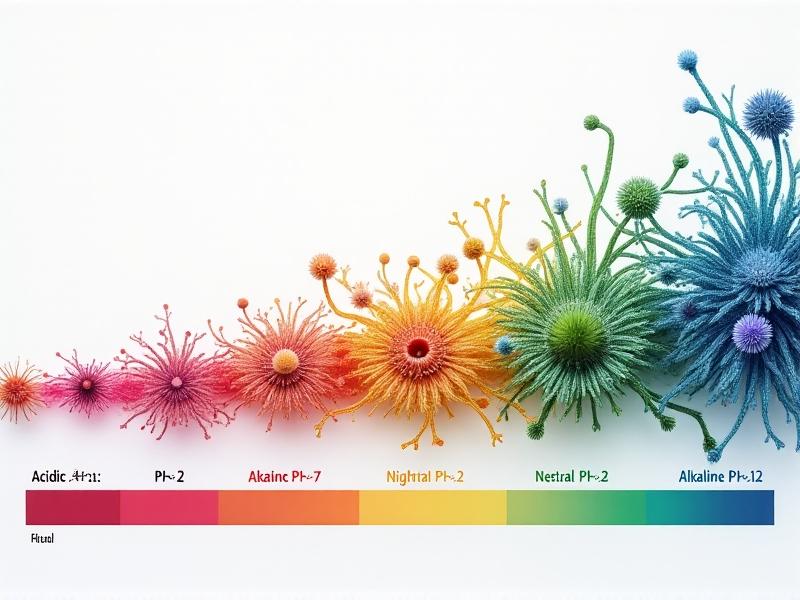

The Role of pH in Microbial Growth and Pathogen Survival

Microorganisms, including harmful pathogens, thrive within specific pH ranges. Most bacteria prefer neutral conditions (pH 6.5–7.5), while fungi and molds tolerate slightly acidic environments. Adjusting pH levels outside these ranges disrupts cellular functions, inhibiting growth or causing death. For example, alkaline conditions can denature proteins, whereas acidic environments interfere with enzyme activity. Understanding these thresholds is critical for industries like food processing and water treatment, where pH manipulation serves as a frontline defense against contamination.

How Acidic and Alkaline Environments Disrupt Pathogens

Pathogens rely on stable internal pH to maintain metabolic processes. When external pH shifts, microbial cells expend energy to balance their intracellular environment, diverting resources from growth. In highly acidic settings, hydrogen ions penetrate cell membranes, breaking down DNA and collapsing proton gradients. Alkaline conditions, meanwhile, saponify lipids in cell membranes, leading to structural collapse. For instance, Helicobacter pylori, a stomach pathogen, survives acidity by producing urease, but most pathogens lack such adaptations. Tailoring pH to target vulnerabilities in specific pathogens enhances control strategies.

pH Adjustment in Food Preservation and Safety

The food industry has long used pH adjustment to extend shelf life and prevent spoilage. Fermentation, for example, lowers pH through lactic acid production, inhibiting pathogens like Clostridium botulinum. Commercial pickling employs vinegar (acetic acid) to achieve pH levels below 4.6, effectively neutralizing Salmonella and E. coli. Regulatory agencies, such as the FDA, mandate pH thresholds for canned goods and dairy products. Modern techniques combine pH control with thermal processing for enhanced safety, ensuring foods remain pathogen-free without compromising taste or texture.

Water Treatment: Balancing pH for Pathogen-Free Systems

In water treatment, pH adjustment optimizes disinfection. Chlorine, a common disinfectant, is most effective at pH 6.5–7.5. At higher pH levels, its efficacy drops as hypochlorite ions dominate. Conversely, acidic water can corrode pipes, leaching metals and creating secondary hazards. Facilities often use lime or carbon dioxide to fine-tune pH before chlorination. Emerging methods, like electrochemical pH modulation, offer precise control for large-scale systems, reducing reliance on chemical additives while maintaining microbial safety.

Agricultural Applications: Soil and Crop Protection

Soil pH influences plant health and pathogen prevalence. Fungi like Fusarium thrive in acidic soils, damaging crops. Applying agricultural lime (calcium carbonate) raises pH, suppressing fungal growth and improving nutrient uptake. Hydroponic systems use pH-adjusted nutrient solutions to prevent root rot and bacterial infections. Precision agriculture tools, such as IoT pH sensors, enable real-time adjustments, minimizing disease outbreaks. This approach reduces dependency on fungicides, aligning with sustainable farming practices.

Challenges in Maintaining Optimal pH for Pathogen Control

While pH adjustment is powerful, it faces practical hurdles. Natural buffers in organic matter can resist pH changes, requiring higher additive doses. In wastewater, fluctuating microbial loads complicate consistency. Over-acidification risks damaging infrastructure or harming beneficial microbes. Advanced systems now integrate automated dosing and real-time monitoring to address these challenges, but cost and complexity remain barriers for smaller operations. Balancing efficacy, safety, and cost is an ongoing focus in research.

Innovations in pH Modulation for Health and Safety

Recent advancements include nanotechnology-based pH sensors and biodegradable acidulants for gradual pH adjustment. Researchers are engineering bacteriophages that amplify acidity in localized areas, targeting pathogens without broad environmental impact. In healthcare, pH-responsive wound dressings prevent infections by maintaining slightly acidic conditions. These innovations promise more precise, sustainable pathogen control, bridging gaps between traditional methods and modern needs.