Automated Climate Control for Grow Rooms

The Importance of Climate Control in Modern Agriculture

In controlled-environment agriculture, maintaining optimal climate conditions isn’t just a luxury—it’s a necessity. Grow rooms, whether used for cannabis, leafy greens, or ornamental plants, rely on precise temperature, humidity, and CO2 levels to maximize photosynthetic efficiency. Even minor deviations can stunt growth, invite pests, or reduce yields. Automated climate control systems eliminate human error, providing real-time adjustments that mimic ideal natural conditions while conserving resources like water and energy.

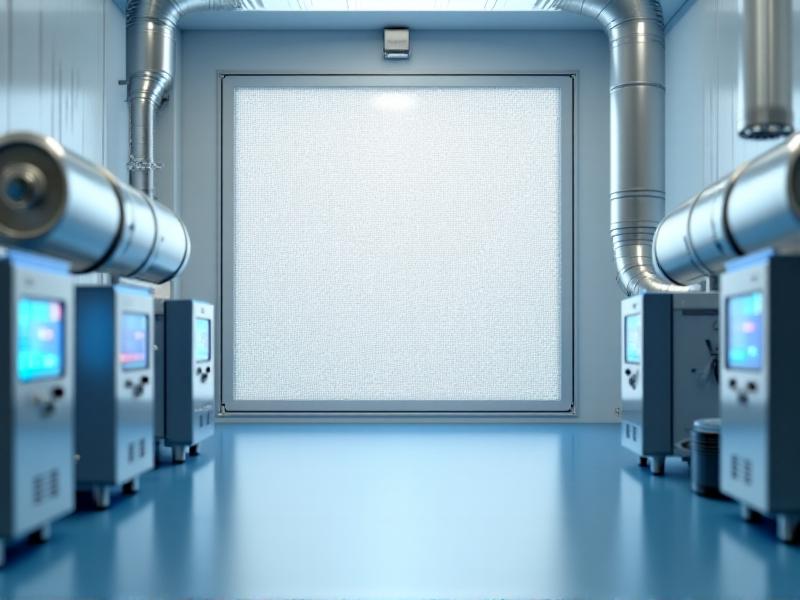

Core Components of an Automated System

At its core, an automated climate control system integrates three key elements: sensors, controllers, and actuators. Sensors monitor environmental variables such as temperature, humidity, CO2 concentration, and light intensity. Controllers—often powered by AI algorithms—process this data to make decisions. Actuators, like HVAC units or dehumidifiers, execute these commands to maintain balance. Together, these components create a closed-loop system that operates seamlessly, ensuring stability even during external fluctuations like heatwaves or storms.

Sensor Technology: The Eyes and Ears of Automation

Modern sensors are the backbone of climate automation. Infrared thermometers measure leaf temperature to detect stress, while capacitive humidity sensors track airborne moisture with 99% accuracy. CO2 sensors use non-dispersive infrared (NDIR) technology to optimize gas levels for photosynthesis. These devices feed data into the system continuously, enabling predictive adjustments. For example, a spike in humidity could trigger preemptive dehumidification before condensation promotes mold growth.

Smart Controllers: The Brain Behind the Operation

Controllers transform raw sensor data into actionable insights. Using machine learning, these systems learn from historical patterns to anticipate needs. For instance, if a grow room typically cools by 2°C at night, the controller preemptively adjusts HVAC settings. Some systems even integrate weather forecasts, reducing energy use by aligning indoor conditions with external trends. User-friendly interfaces allow growers to set custom parameters, such as VPD (vapor pressure deficit) targets for specific growth stages.

HVAC Systems: Precision Airflow and Temperature Management

Heating, ventilation, and air conditioning (HVAC) systems must work in harmony to avoid hotspots or energy waste. Variable-speed fans adjust airflow based on real-time needs, while heat pumps recover energy from exhaust air. For vertical farms, laminar airflow designs ensure even distribution across stacked grow trays. Some setups use geothermal cooling or solar-powered chillers to enhance sustainability. The result? Consistent microclimates that support robust plant development.

Benefits: Higher Yields, Energy Efficiency, and Disease Prevention

Automation directly translates to tangible benefits. Studies show that optimized VPD levels can increase cannabinoid production in cannabis by up to 30%. Energy recovery ventilators cut electricity costs by 40%, while predictive algorithms reduce water usage. Perhaps most crucially, stable environments deter pathogens—automated systems can detect and neutralize threats like powdery mildew before they spread, protecting entire crops without chemical interventions.

Overcoming Challenges: System Reliability and Maintenance

Despite their advantages, automated systems aren’t foolproof. Calibration drift in sensors or software glitches can disrupt operations. Redundant sensors and fail-safe protocols are essential—for example, backup power supplies during outages. Regular maintenance, like cleaning air filters or updating firmware, ensures longevity. Growers must also balance automation with human oversight, intervening when anomalies arise that algorithms might misinterpret, such as a sensor malfunction mimicking a climate emergency.

Future Trends: AI, Machine Learning, and Vertical Farming Integration

The next frontier involves AI models trained on petabytes of agricultural data to predict plant needs days in advance. Imagine a system that adjusts nutrient delivery based on leaf color changes detected by cameras. Vertical farms in urban warehouses will leverage IoT-enabled climate grids, where each growth layer operates independently. Meanwhile, quantum computing could optimize entire supply chains, dynamically aligning climate settings with market demand to minimize waste.

Selecting the Right System for Your Grow Room

Choosing an automated system depends on scale, crop type, and budget. Small growers might opt for modular kits with plug-and-play sensors, while commercial facilities require custom solutions. Key considerations include scalability (can the system handle more sensors?), compatibility (does it integrate with existing irrigation?), and support (24/7 troubleshooting?). Third-party certifications like CE or UL listing ensure safety and performance reliability.

Real-World Success Stories: Case Studies in Automation

In Colorado, a cannabis farm saw a 25% yield boost after automating CO2 and humidity control. A Tokyo vertical farm reduced energy costs by 60% using AI-driven HVAC. Meanwhile, a Dutch tomato greenhouse achieved year-round production by syncing climate settings with supplemental lighting. These examples prove that automation isn’t just theoretical—it’s a transformative tool already reshaping global agriculture.