Air Filtration Systems for Contamination

The Essential Role of Air Filtration Systems in Modern Contamination Control

Air filtration systems have become a cornerstone of maintaining safe indoor environments, from hospitals to manufacturing plants. These systems are designed to capture and neutralize contaminants that threaten air quality, health, and operational integrity. With advancements in technology and increased awareness of airborne risks, understanding how these systems work—and why they matter—is critical for industries and households alike.

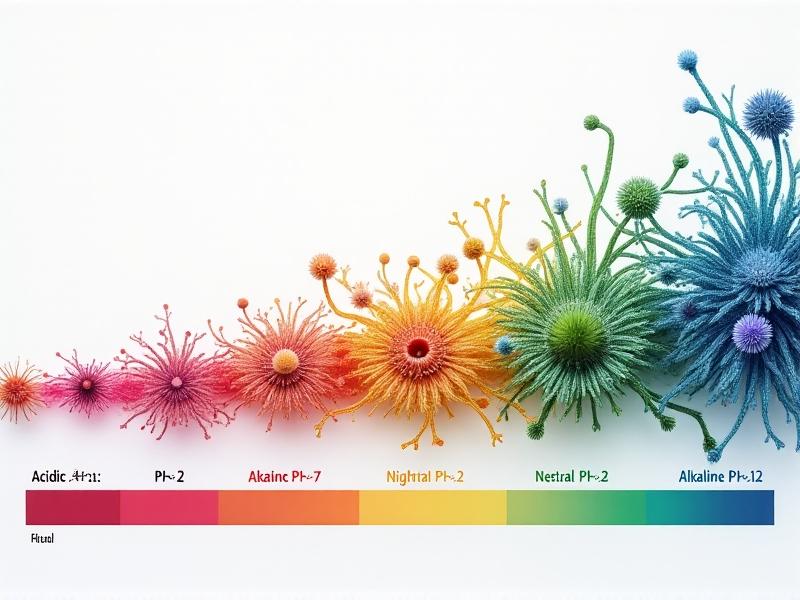

Understanding Airborne Contaminants: Types and Threats

Airborne contamination comes in three primary forms: particulate matter (dust, pollen, smoke), biological agents (bacteria, viruses, mold), and chemical pollutants (VOCs, fumes). Particulate matter can exacerbate respiratory conditions, while biological contaminants pose infection risks. Chemical pollutants, often undetectable by smell, contribute to long-term health issues. Effective air filtration requires systems tailored to these specific threats.

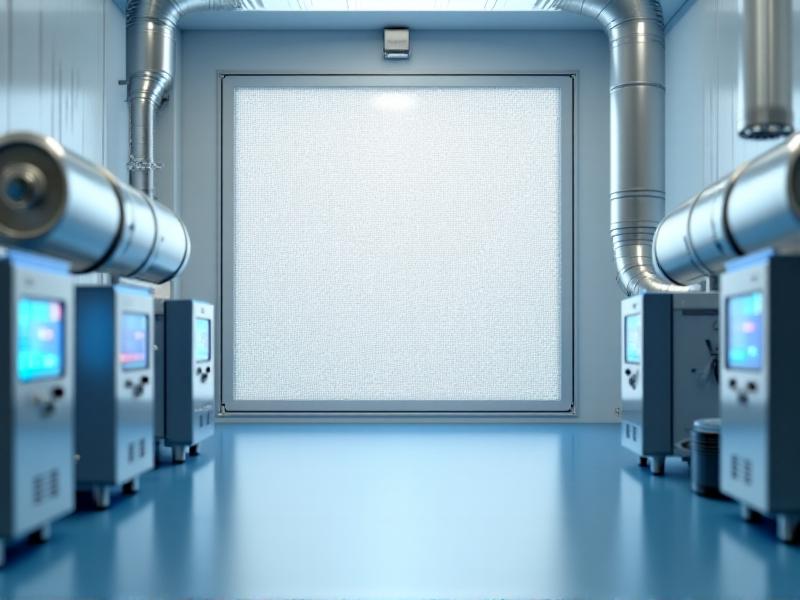

HEPA Filters: The Gold Standard for Particulate Removal

High-Efficiency Particulate Air (HEPA) filters capture 99.97% of particles as small as 0.3 microns, making them indispensable in healthcare and cleanrooms. Their dense fiber matrices trap pollutants through interception, impaction, and diffusion. However, HEPA alone doesn’t address gases or odors, necessitating complementary technologies. Regular replacement is crucial to prevent clogging and maintain airflow efficiency.

Activated Carbon and Chemical Adsorption Solutions

Activated carbon filters excel at adsorbing gaseous pollutants through a vast network of microscopic pores. These filters are particularly effective against volatile organic compounds (VOCs) emitted by paints, cleaners, and building materials. Newer hybrid systems combine carbon with potassium permanganate to break down complex chemicals. Industries like automotive manufacturing rely on these to mitigate toxic fumes.

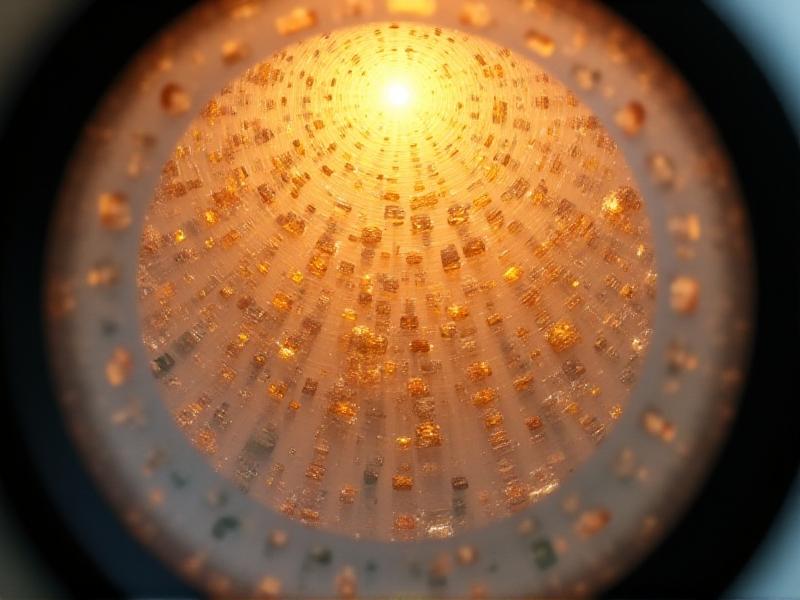

UV-C Light and Biocidal Filtration Technologies

Ultraviolet germicidal irradiation (UVGI) systems use short-wavelength UV-C light to disrupt microbial DNA, neutralizing pathogens like influenza and MRSA. When integrated into HVAC systems, they provide continuous disinfection. However, proper positioning and lamp intensity are critical—poorly designed UV setups may leave shadows where pathogens survive. Recent advancements include reflective chambers to maximize exposure.

Smart Air Filtration: IoT and Real-Time Monitoring

Modern systems integrate IoT sensors to track particulate levels, humidity, and VOC concentrations in real time. Cloud-connected purifiers auto-adjust fan speeds based on sensor data, while mobile apps provide air quality histories. Facilities like data centers use predictive algorithms to schedule filter changes, reducing downtime. These smart systems also detect filter tampering or leaks, enhancing compliance in regulated industries.

Customizing Systems for Industry-Specific Needs

Pharmaceutical labs demand ISO-classified cleanrooms with HEPA and ULPA filters, while commercial kitchens prioritize grease extraction. Nuclear facilities employ absolute filters with negative pressure containment. Retrofitting older buildings often involves modular units that bypass structural limitations. Case studies show semiconductor manufacturers reducing defect rates by 40% after upgrading to multi-stage filtration suites.

Maintenance Strategies for Long-Term System Efficacy

Neglected filters become contamination sources themselves. Best practices include pressure-drop monitoring, leak testing with PAO aerosols, and adherence to ASHRAE standards. Some hospitals use RFID-tagged filters to track lifespan. Energy costs can spike by 15% if clogged filters restrict airflow, making scheduled maintenance both a safety and economic imperative.

The Future of Air Filtration: Sustainability and Innovation

Researchers are developing plant-based filters using moss enzymes to break down VOCs, while graphene-based membranes promise higher efficiency with lower resistance. Solar-powered nano-filters are emerging for off-grid applications. The push toward circular economy models has led to fully recyclable filter cartridges, reducing landfill waste from disposable systems.